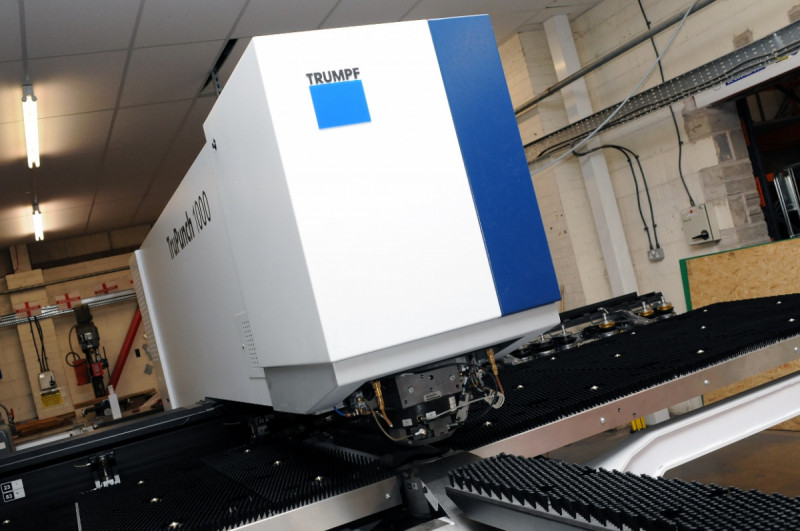

CMD Ltd, the specialist in underfloor power systems and workstation connectivity, has invested in a new £1/4M TRUMPF CNC metal punch which will be used in the production of a wide variety of CMD’s products at the company’s Rotherham factory as part of an asset renewal strategy.

Suitable for handling sheet metal between 0.9mm and 3.0mm thick, the new machine will replace one of two existing CNC machines, while the other legacy machine remains in service, ensuring uninterrupted production at the company while the new asset is installed and commissioned. Once the old machine has been fully decommissioned, it will be shipped to new owners in Lithuania.

The CNC metal punching machines are used in the production of a wide variety of products, including CMD’s underfloor Power Hub System, floor boxes and grommets and many of the brackets and components across the range.

Roger Byrne, Head of Manufacturing at CMD Ltd explains, “To maintain the quality of our output and ensure we have the capacity and resilience to provide uninterrupted, reliable supply to our customers, we are retiring our old CNC machine to make way for a new model. The new asset will require less maintenance and ensure rapid availability of any spare parts, reducing the risk of unplanned downtime and ensuring we continue manufacturing at full capacity to meet demand.”

The new TRUMPF CNC Machine will be fully operational at CMD’s factory by the end of October, following installation, commissioning and training of the company’s team. It will be both quieter and more energy efficient, contributing to the company’s environmental goals and ISO 9001 accredited quality systems. A full summary of the new machine’s features and capabilities is outlined in this video: https://www.youtube.com/watch?v=AHbgO8A_zO4

Two new operators have been appointed and join the company’s existing CNC team and they will all undergo four days of external training provided by TRUMPF.

General manager of CMD Ltd, Jon Holding adds: “Our commitment to customers is to provide innovation, quality and reliability of supply. Replacing our equipment before it reaches the end of its service life is a key element in delivering that promise”.

“This investment will help us maintain high standards of quality and consistent output and we will continue to prioritise the efficiency of our UK manufacturing operations to ensure we remain a trusted supply chain partner.”